Press Conference (2024/10/17)

To achieve carbon neutrality, it is necessary to enhance the energy efficiency of power devices used in household appliances, electric vehicles, industrial machinery, and renewable energy systems.

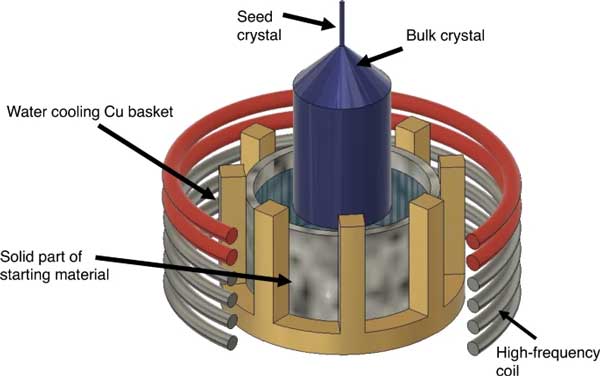

Compared with traditional wide bandgap materials, such as SiC or GaN, β-Ga₂O₃ is expected to help realize energy-saving power devices with higher performance owing to its wider bandgap (4.5–4.9 eV). Additionally, Similar to silicon (Si), β- Ga₂O₃ can be grown from a melt; therefore, β-Ga₂O₃ is expected to have single crystal substrates (wafers) with comparable low-cost and high-quality characteristics.

Nevertheless, at present, the most widely used growth methods for bulk oxide single crystals require the use of precious-metal crucibles. Growing high-melting-point-oxide-crystals requires expensive iridium (Ir) crucibles, which leads to high production costs for single-crystal substrates as market price of Ir is approximately 170US$/g as of August 2024 and need for periodic reprocessing. Consequently, Reese et al. suggested that Ir related costs are over 60% of the manufacturing cost in the β- Ga₂O₃ semiconductor substrate and epitaxial process, which makes it highly challenging to reduce the manufacturing cost of β- Ga₂O₃ devices.

Here, β- Ga₂O₃ substrates are more expensive than SiC substrates, hindering their widespread adoption.

To address this challenge, we have established FOX Corporation, a startup from Tohoku University and a carve-out from C&A Corporation. Supported by investments from Macnica Investment Partners, Iwatani Venture Capital, and Tohoku Tech Ventures.

Publication Details

Title

Authors

Journal

DOI

Online publication date

June 27, 2024

Press release online (in Japanese)

PDF: 625 KB