Conventional transportation equipment relies heavily on steel. But steel is heavy, and scientists are turning to alternatives in the quest to improve the safety and speed of transportation, whilst simultaneously lessening its environmental footprint.

Magnesium alloys, with their low density and excellent strength-to-weight ratio, are considered the next-generation base metal for multi-material design and have been touted as a possible replacement for conventional steels when appropriate.

Although progress has been made in overcoming certain weaknesses associated with magnesium alloys, such as flammability, developing bonding technology that bonds magnesium alloys with structural steels has been severely limited because magnesium and iron are immiscible and do not form at the alloy phase.

Yet, a research group from Tohoku University has succeeded in establishing a dealloying bonding technology that obtains a strong mechanical bond between iron and magnesium.

Kato also points out that this approach provides an ideal mechanical bonding method that creates a strong anchoring effect between materials that cannot form strong bonds.

The breakthrough was reported in the journal Scripta Materialia on March 16, 2023.

Looking ahead, the research group plans to harness the advance dealloying technique to bond immiscible dissimilar materials and produce new light-weight materials that reduce the fuel consumption of automobiles, trains, and airplanes.

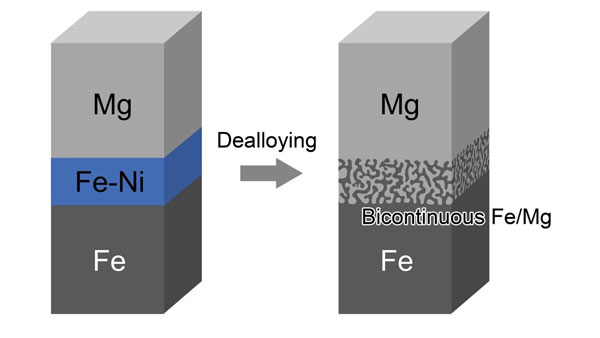

A Schematic illustration representing the dealloying bonding of iron and magnesium. Firstly, the iron-nickel layer is bonded on the top of the iron. Subsequently, Mg is attached and heated. Then, the dealloying reaction of nickel elements selectively diffuses into magnesium. Meanwhile, the developing bicontinuous structure of iron and magnesium occurs. Due to the anchor effect of such a structure, iron and magnesium was strongly bonded even though they are immiscible.

Publication Details

Authors

Journal

DOI

10.1016/j.scriptamat.2023.115404

Online publication date

March 16, 2023

Press release online (in Japanese)

PDF: 611KB